Category

Polyurethane (PU) Gasket Foam Seal Dispensing Machine

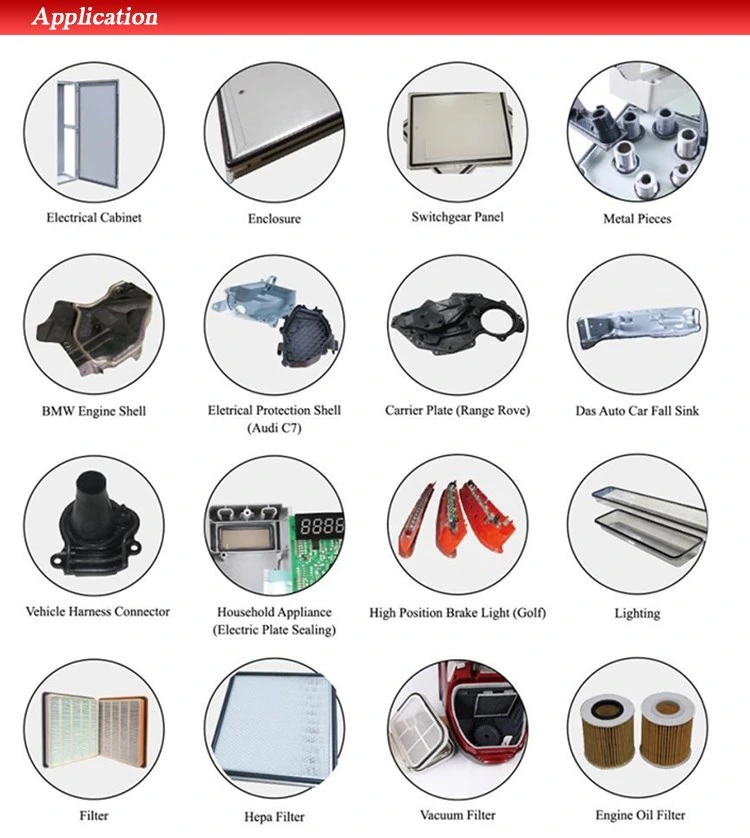

DS-20 Polyurethane(PU) Gasket Foam Seal Dispensing Machine Machine Picture USES Is mainly used for cabinets, distributio

Basic Info.

| Model NO. | DS-20 |

| Controller | Leadshine |

| Gasket Width | 5-30mm |

| Operating Method | Touch Screen/Keyboard/ Buttons |

| Interface | Touch Screen |

| Repeated Position Precison | +-0.05mm |

| Air Pressure | 6-8 Bar |

| Output | 1-4 G/S |

| Mixing Ratio(a:B) | 1:1-10:1 |

| Overall Space | 4100X2700X2100mm (L*W*H) |

| Working Stroke | 2300X1250X200mm (X*Y*Z) |

| Model | Ds-20(Standard) |

| Operating System | Ds-20 Based on Windowsxp/Win 7 |

| Components | 2 Components(a+B) |

| Name | Polyurethane |

| Weight | 1900 Kgs |

| Transport Package | Plywood Wooden Case |

| Specification | 250MM(X)*1250MM(Y)*200MM(Z) |

| Trademark | SME |

| Origin | Shanghai China |

| HS Code | 8479899990 |

| Production Capacity | 500 Pieces/Year |

Product Description

DS-20 Polyurethane(PU) Gasket Foam Seal Dispensing Machine- Machine Picture

- USES

- Sample

4. Performance Characteristics

1 German technical , independent research on operate control system,adopt intelligent humanity-machine display screen.

2. Using System intelligent operation analogue function to eliminate the machining problem caused by artificial size problem completely in production process;

3. Intelligent low-pressure alarm function to avoid Producing bad products caused by unstable air pressure in the equipment work .

4 Hand-held interface makes operation simple easy,human resource was saved and needs of various customers is satisfied;5 .The hardware part of the system using America DSP.

5.Technical Parameter

| Items | Parameters/Brand |

| model | DS-20(standard) |

| overall space | 4100X2700X2100mm (L*W*H) |

| working stroke | 2300X1250X200mm (X*Y*Z) |

| weight | 1900 KGS |

| name | polyurethane |

| components | 2 components(A+B) |

| operating system | DS-20 based on WindowsXP/Win 7 |

| interface | touch screen |

| operating method | touch screen/keyboard/ buttons |

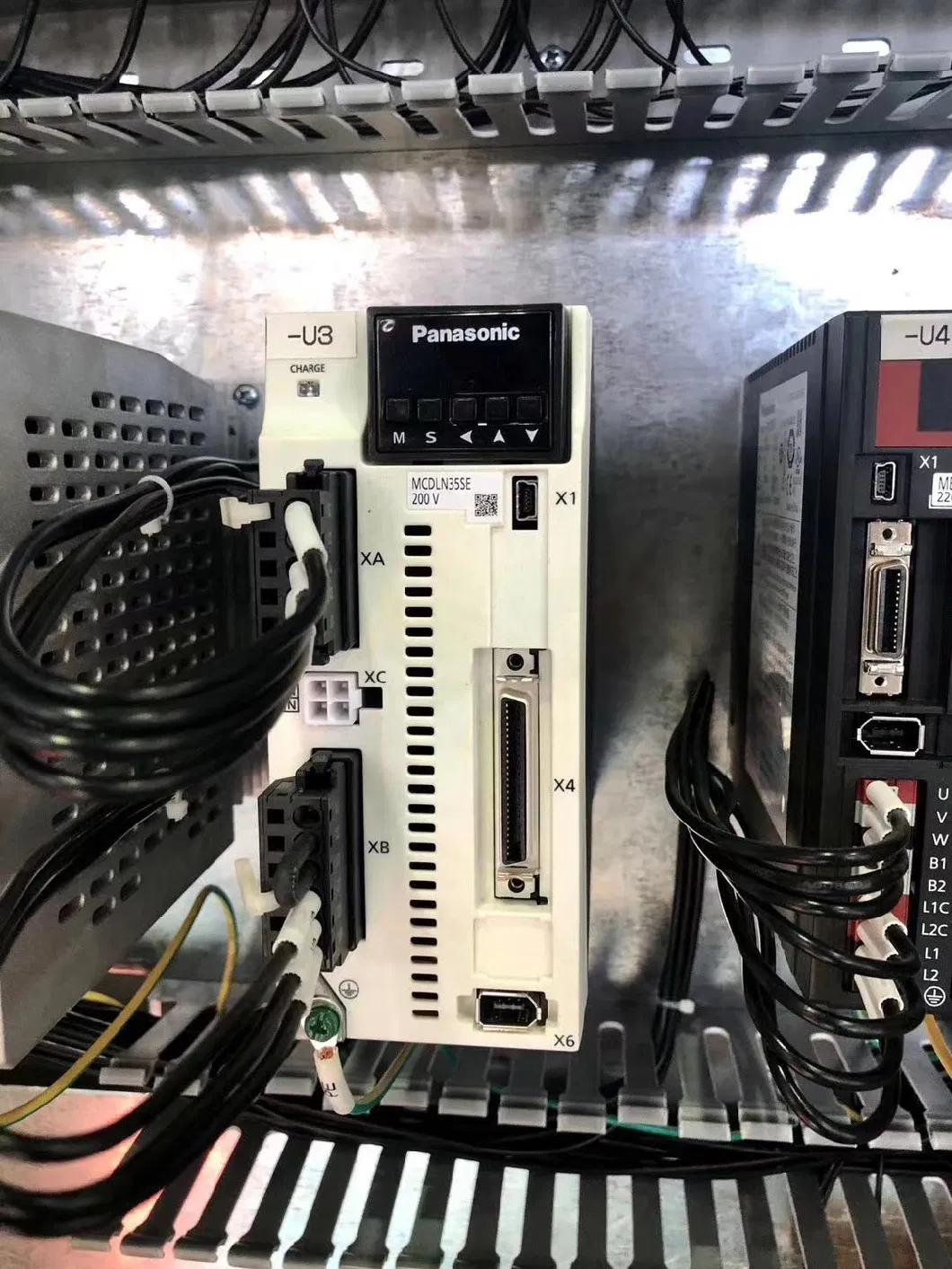

| controller | Leadshine |

| screen size | 12.1" |

| mixing head | model | MD-600 | ||

| gasket width | 5-30mm | |||

| clean method | high pressure water clean+ air-blow cleaning | |||

| mixing ratio(A:B) | 1:1-10:1 | |||

| output | 1-4 g/s | |||

| repeated position precison | ±0.05mm | |||

| air pressure | 6-8 bar | |||

| metering pump | brand | Barmag | ||

| model | A-3cc/r B-0.6cc/r | |||

| mechanical frame | type | 3-aix linear mechanical arm | ||

| speed | 0-250mm/s | |||

| rail brand | HIWIN (Taiwan) | |||

| gear-rack brand | China brand | |||

| servo motor | Panasonic | |||

| speed reducer | BGT(Taiwan) | |||

| storage tank | type | air pressure tank |

| volume | A tank-40L B tank-40L | |

| automatic stirring | A tank:YES B tank: NO | |

| glue refill | manual | |

| air refill | automatic | |

| automatic refill station | optional | |

| working table | material | aluminum profiles |

| size | 2000X1000X900mm (L*W*H) | |

| electric power | voltage | 3X380V |

| powder | 5.5kw | |

| air | dry compressed air | ≥6bar |

| water | clean tap water |

Configuration:--mobile operating console--mixing and dispensing devices--mechanical frame--electrical control panel--storage tanks--standard working table Options:--automatic material filling station--customized working table

7 Mixing Head

Model: MD-600

Dimension :410*200*135MM

Weight:4.6Kgs

Color:Silver

Output:1-4g/s

Repeated Glue Output Precision:1%(Weight Test)

Pressure Control Method:

Electromagnetic Valve

Description:

- high pressure water-cleaning and air-cleaning

- use sensor pneumatic and vibrating film principle to control glue feeding and cycling

- modular light-weight structural design;

- high strength aluminum alloy and stainless steel structure;

- multiple level glue injecting

- stirring bar speed is adjustable, special design makes glue mixing very even

- high pressure pinhole injecting valve to control water-cleaning

- air-blow pinhole injecting valve to dry mixing head

- stirring bar directional movement to control the nozzle locking function

- feeding valve has water heating and cycling function

Raw Material-PUPU is a product of 2-component Polyurethane. It adopts FIPFG (foamed-in-place foam gasket) technology which can foam on theworkpiece directly. The finished product is a soft and elastic foamed gasket. This gasket is made from component A and componentB. Component A is mainly polybasic alcohol, Component B is a hardener-isocyanate. After mixing A and B according to a certainproportion and completely foaming, the mixture will become a soft foamed sealing strip.• Mixing time: time for mixing component A and component B• Reaction time: time for the mixture to react( about15-60 seconds after mixing)• Foam time: time from reaction to finish (about 15-180 seconds)• Dry time: time for no viscosity on the suface, and no damage with touch under room temperature 25 ºC(about 2-20 minitues later)• Available time:time for the availability of gasket to be pressed or assembled (about 20 minitues-12 hours later)

VII Raw Material Tank

1,Stainless steel 316 double pressure tank is capable of storing 20L material;

2,No material alarm intelligent control ensures that the raw materials in the production are sufficient;

3,The automatic mixing function of A tank can guarantee that the raw material is not layered in the state of long-time no use;

4,Intelligent temperature control device (-15 ºC - + 45 ºC) ensures that raw materials can be used normally at low temperatures;

5,The air compensating function of A material makes the chemical structure of A material(polyurethane) more stable.

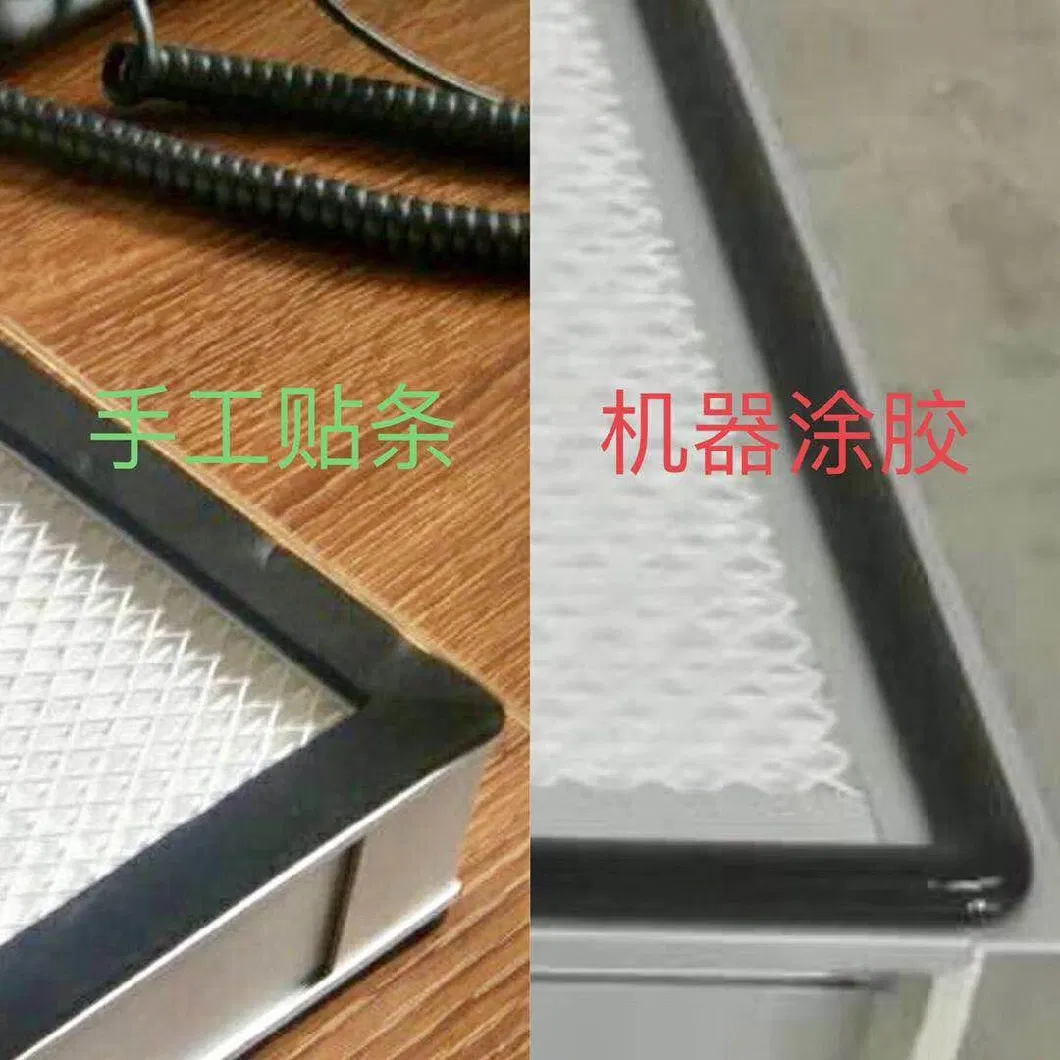

8. Why USE GASKET MACHINE

By Hand By Machine

9 Detailed Picture

Delivery Picture

12. Payment and Shipping

13. About us

SME Polymer Solutions has been developing and Manufacturing innovative sealing systems based on Polyurethane and Silicone. SME systems combine top Quality with exceptionally easy handling. Key Features include Low water Absorption, good adhesion, high long-term Temperature resistance, and a cost-efficient manufacturing process.

Polymer develop, produces and distributes worldwide polymer sealing ,gluing and potting systems on polyurethane, silicon and PVC basis. Their performance is based on the experience of more than thousand formulations . The sealing material is applied onto structural components and modules of OEMs and industrial suppliers by the FIPFG/FIP (Formed-in-Place Foam Gasket/Formed-in-Place) technology

Main product: 2/3-components FIPFG sealing solutions equipment, PU Foam Sealing Equipment, Microscale Sealing System, Cabinet Sealing Machine, Lightings Sealing Gasket Machine, Automatic Car Sealing System, Silicon Sealing equipment, Dispensing Machine, Spreading Equipment, Gluing Machine, Thermally Insulating Aluminum Profiles Gluing & Cutting Equipment, Custom-made Machineries etc.

We welcome any comments and questions you may have about our products or any other aspect of our business.

We value your feedback as we are always looking for opportunities to provide better service.