Three Component Rotary Casting Polyurethane Elastomer Pouring Machine for Car Wheel

Basic Info.

| Model NO. | QB |

| Computerized | Computerized |

| Certification | CE, ISO9001:2008 |

| Chain Extender | Tdi/Mdi/Mdq/Moca/Bdo, etc. |

| Advantage | Cheap Price, High Efficiency |

| Dual Function | Conventional Casting or Rotary Casting |

| Product Name | Three Component Elastomer Pouring Machine |

| Transport Package | Standard Package |

| Trademark | Henghui |

| Origin | China |

| HS Code | 8477101090 |

| Production Capacity | 50 Set |

Product Description

Product Description

QB Series Three Component Elastomer Pouring MachineUse:It is used for the production of TDI. MDI, MDQ series of MOCA. BDO and other chain extender polyurethane, can meet the conventional casting or rotary casting process requirement.Characteristic:1. The measure is accurate, the mixture ratio inaccuracy is less than < ± 0.3%;2.Misce bene, the innovative mixing organization, dependable performance;3.Heated air circulation heating, keep temperature error < ± 2 0C4.The fire-new discharge valve, good vacuum degree, the product is macroscopy and free of blowholes;5.The color sizing and additive join the mixing head directly, reduction of cost, increase efficiency.

Detailed Photos

Product Parameters

Parameters:

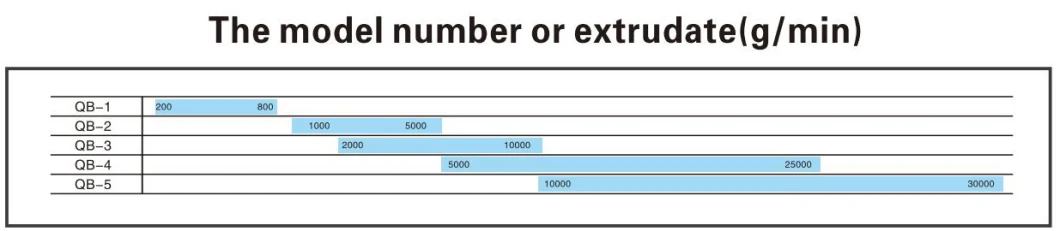

| TYPE | OUTPUT (g/s) |

| QB-1 | 200-800 |

| QB-2 | 1000-5000 |

| QB-3 | 2000-10000 |

| QB-4 | 5000-25000 |

| QB-5 | 10000-30000 |

→ More Low Pressure PU Foam Machines Please Contact Us.

Company Profile

Founded in 1999, Zhejiang Henghui Machinery Co., Ltd. is the backbone enterprise of polyurethane equipment in China. It has a group of engineers and technicians with rich production experience and dedication. In June 2003, the company passed the IS09001:2000 international quality system certification, and now produces more than 100 sets of polyurethane equipment of various types.At present, more than 1,000 sets of equipment are running all over the world. Products mainly include polyurethane low-pressure foaming machine (low-pressure polyurethane foaming machine), polyurethane elastomer pouring machine (elastomer pouring machine), polyurethane high-pressure foaming machine (high-pressure polyurethane foaming machine), sealing strip forming machine (sealing strip equipment), etc., can be customized on demand through close cooperation, so that customers can optimize production process and improve industrialization, so that Henghui polyurethane production facilities. Get the trust of a large number of users.The enterprise has become a famous polyurethane equipment manufacturer in East China. Henghui has its own machinery, electronic control, software development and design team, a large number of spare parts in stock, which strongly ensure that you optimize timely service, as well as excellent performance of polyurethane equipment. Henghui constantly provides customers with more high-performance and more practical production equipment, production process practice and experience, so that we have the ability to provide comprehensive support to customers, product development and optimization with customers.Certification:Packaging & Shipping

Our Advantages

1.The machines are not customized and are made according to customers' requirements.

2.We have a group of engineers and technicians with rich production experience and dedication THE.

3.There are polyurethane low-pressure foaming machine, polyurethane high pressure machine, polyurethane elastomer pouring machine, sealing strip equipment and, etc.4.Henghui machines are non-calibrated and can be manufactured according to customer's requirements.5.Henghui has its own machinery, electronic control, a larger number of spare parts in stock, which strongly guarantee the quality of your service.

After Sales Service

1. All life time service 2. One year warranty 3. Online technical support4. Professional after sales service team

FAQ

1. Are you factory or foreign trade company?Factory.2. Where is your factory located? Our factory is located in Wuyi county, Zhejiang Province, near Yiwu city.3.How about your company's after-sales service?We provide online service and technical support. If necessary On-site service can be offered as well.4.How long is your product warranty?ONE year warranty.