Category

KW

kw520CD Coated sealing strip door pu seal and gasket casting making pouring foaming machine production line Application

Basic Info.

| Model NO. | KW-520CD |

| Weight | 1900 Kg |

| Warranty | One Year |

| Transport Package | Wooden Case/ Carton |

| Specification | 2000X1800X1900mm |

| Trademark | KAIWEI |

| Origin | China |

| HS Code | 8479899990 |

| Production Capacity | 200 Sets/Year |

Product Description

kw520CD Coated sealing strip door pu seal and gasket casting making pouring foaming machine production lineApplication

KW-520CD is widely applied for car, cabinet/box, air filter, air-conditioning puring equipment, packing, electrical element, light, new energy, etc.

Feature

Material: PU

Stroke:1000X8000X200mm(X*Y*Z)

Working table:2000*1000mm(L*W)

Mixing head: KW600

Finished gasket width 5-30mm.

| Items | Parameters | |

| Machine | Model | KW-520CD |

| Overall space | 4000X3300X2300mm (L*W*H) | |

| Working effective stroke | 2300X1250X200mm (X*Y*Z) | |

| Weight | 1900 KGS | |

| Chemical material | Name | Polyurethane |

| Components | 2 Components (A+B) | |

| System/operation | Operating system | Win 7/10 |

| Operating method | Keyboard/ Buttons | |

| Mixing head | Model | KW600 |

| Gasket width | 6-30mm | |

| Clean method | High pressure water clean+ air-blow cleaning | |

| Mixing ratio(A:B) | 1∶1-10∶1 | |

| Output | 1-4 g/s | |

| Repeated position precision | ±0.05mm | |

| Air pressure | 6-8 bar | |

| Mechanical frame | Type | 3-aix linear mechanical arm |

| Speed | 0-250mm/s | |

| Storage tank | Type | Air pressure tank |

| Volume | A Tank-40L B Tank-40L | |

| Automatic stirring | A Tank: YES B Tank: NO | |

| Glue refill | Manual | |

| Air refill | Automatic | |

| Working table | Material | Aluminum profiles |

| Size | 2000X1000X900mm (L*W*H) | |

| Electric power | Voltage | 3X380V ( It can be designed base on customer request) |

| Power | 5.5kw | |

| Air | Dry compressed air | ≥6bar |

| Water | Clean tap water | |

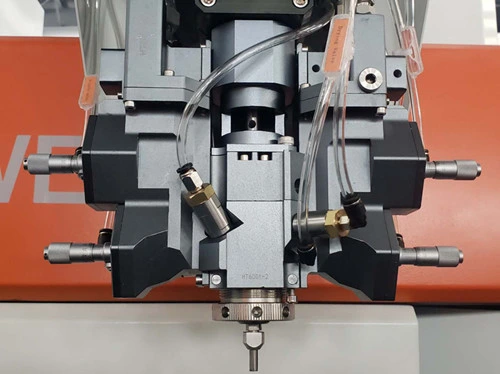

Mixing and Dispensing:

- Mixing head model:KW-600

- Dimension:410*200*135mm

- Weight:4.6KG

- Colour: Silver

- Output:1-4g/s

- Repeated glue output precision:1% (weight test)

- Pressure control method: electromagnetic valve

Description:

- High pressure water-cleaning and air-cleaning

- Modular light-weight structural design;

- High strength aluminum alloy and stainless steel structure;

- Multiple level glue injecting

- Stirring bar speed is adjustable, special design makes glue mixing very even

- High pressure pinhole injecting valve to control water-cleaning

- Air-blow pinhole injecting valve to dry mixing head

- Stirring bar directional movement to control the nozzle locking function

1) Auto Cad is built in the vertical computer; 2) USB port to transfer the Auto Cad drawing to the vertical computer; 3) Gallery with standard pictures in the vertical computer;4) Wireless Hand operator panel for teach in programming;

Metering Pumps:

Germany Barmag metering pumps can assure the precision of glue feeding.

| Name | Brand | Model | Speed(ml/r) | Quantity | Type |

| A feeding valve | Barmag | 1-001-1787 | 3 | 1 set | single inlet and outlet |

| B feeding valve | Barmag | 1-001-1785 | 0.6 | 1 set | single inlet and outlet |

Mechanical Frame:

Mechanical frame is including 3-axis steel welding mechanical arm, gear-rack, rail, servo motor, speed reducer, drag chain, steel base and others.

Steel welding frame can meet the demands of high strength and stability when the machine moves in high speed. Besides, skewed tooth gear-rackcan improve the stability and precision of 3 axes, reduce the noise.

Electrical control panel:

- KAWIEI ES SERIES control panel:1700*1000*400mm(H*W*D)

- Material :mild carbon steel

- Color: RAL9003 RAL2011

- Elements brand:Schneider Omron Siemens and others

- 1,Material:stainless steel

- 2,Volume: A-40L B-40L

- 3,Automatic high-low level alarm for A

- 4,A tank is with automatic glue-stirring and air-refilling function

- 5,A,B tank are with impurity filter

- 6,A tank with automatic air refilling and mixing function

Working table:

- Dimensions:2000*1000*900mm(L*W*H)

- Material:Aluminum profiles

- Desk top:Grey wear-resisting cloth

- Water and air-cleaning stainless box

- Control button box

- Work-piece fixing stainless bars

Raw Material-PU

PU is a product of 2-component Polyurethane. It adopts FIPFG (foamed-in-place foam gasket) technology which can foam on the

workpiece directly. The finished product is a soft and elastic foamed gasket. This gasket is made from component A and component

B. Component A is mainly polybasic alcohol, Component B is a hardener-isocyanate. After mixing A and B according to a certain

proportion and completely foaming, the mixture will become a soft foamed sealing strip.

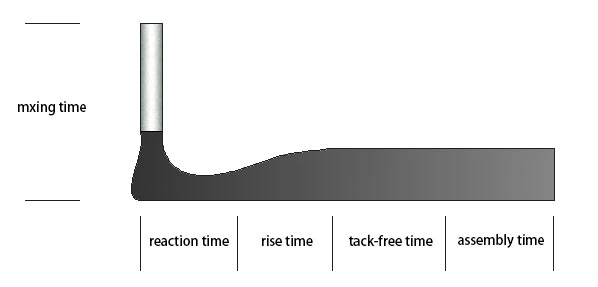

• Mixing time: time for mixing component A and component B

• Reaction time: time for the mixture to react( about15-60 seconds after mixing)

• Foam time: time from reaction to finish (about 15-180 seconds)

• Dry time: time for no viscosity on the suface, and no damage with touch under room temperature 25 ºC(about 2-20 minitues later)

• Available time:time for the availability of gasket to be pressed or assembled (about 20 minitues-12 hours later)

Shanghai Kaiwei Electric Equipment Co.,Ltd.

Website :kaiwei-electric.en.made-in-china.com

Add:Room B618, no.6433 yinggang east road, 8090 pioneer park, qingpu district, Shanghai, China